Pneumatic Conveying

Vacuum Conveying

Vacuum conveying systems are very suitable for other low capacity, short distance, large particule size powders and granular materials used in many areas of industry.

These applications are relatively easy and simple. The projects we have realized include applications where 1 micron grain size powders can be transported with the same performance as well as coarse powder materials. Thanks to its special blower and filter systems, it provides success in heavier duty and high performance vacuum handling operations.

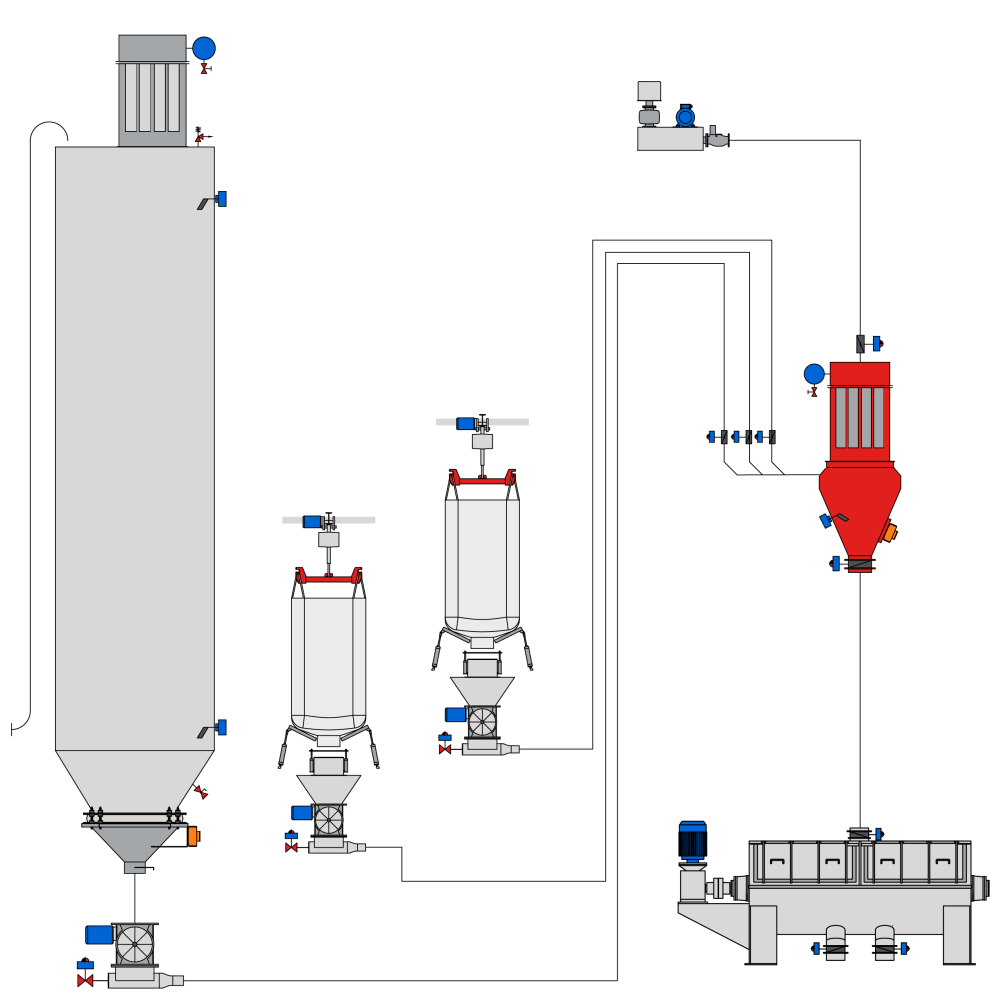

In vacuum conveying systems, the product is sucked from bunker, silo or bigbag units and conveyed to other machines to be fed about production. As a central feeding system, it can be sucked from a single point and multiple extruders, injections, etc. as well as distribution to the machine; It can be used as a weighing vacuum cyclone or as a dosing equipment from multiple points to a single mixer. Thanks to the special techniques we apply, this weighing can be performed with extreme accuracy.

Working Principle and Advantages of the System

In vacuum conveying systems, the material is drawn by a vacuum blower located on the target side of the system to be conveyed. The bulk material is conveyed to the pipeline with equipment such as rotary valve (air lock), venturi or suction nozzle on the side where the product is discharged. With the power of the vacuum created by the blower, it is moved to the target point to be drawn. While the transported material accumulates in the cyclone (vacuum receiver) unit at the target point, clean air is discharged without dust thanks to the special filter system integrated into this structure. Filter design varies from jet pulse filters to simple filter cartridges, depending on the characteristics of the material to be transported.

- It is suitable for all bulk raw materials, including fine-grained powders and granules.

- In addition to short distance applications, it also provides maximum efficiency at distances up to 50 meters.

- It is suitable for the assembly of equipment such as on-line sieve, magnetic separator, which increases the process quality.

- A weighing system suitable for recipe production can be adapted for use in mixer feeding.

- It can be used to feed the filling bunkers of volumetric or gravimetric feeders.

| CleanJet Filter Technology

VacuMate is integrated with VOLDE's proprietary CleanJet dust filter technology. This specialized filter system is optimized based on the characteristics of the transported material, preventing dust formation while releasing clean air into the atmosphere. The VacuMate vacuum conveying system can efficiently transport all types of materials, including fine dust particles below 1 micron.

| User-Friendly and Efficient Operation

The system continues the product retrieval process until the desired level or weight is reached, using a user-friendly interface. Once the conveying process is complete, automatic unloading and filter cleaning processes take place. Continuous processing with the use of a rotary valve is possible as needed.

With its high capacity and precision in transporting fine dust, the VacuMate Vacuum Conveying System offers innovative, reliable, and efficient solutions for industrial conveying and processing needs. VOLDE's pioneering technology is designed to meet the efficiency and performance requirements of the industry.