PVC Mixer Feeding

Perfect PVC Mixes According to Recipe

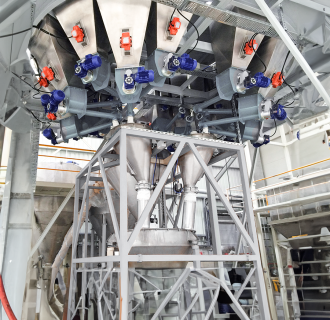

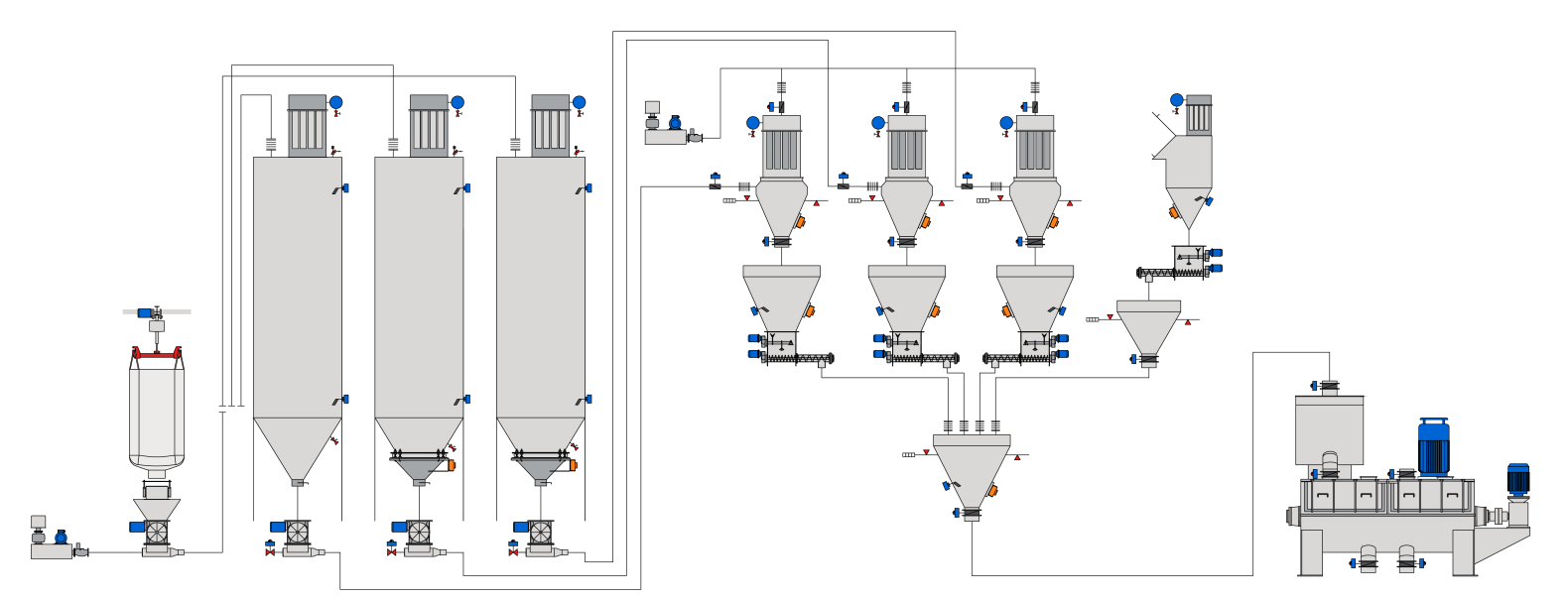

At VOLDE, we aim to enhance the efficiency and product quality of your production process with our PVC mixer feeding systems developed for PVC window profile manufacturing facilities. These systems ensure the automatic weighing and feeding of powdered raw materials into mixers, guaranteeing the optimization of your production processes and quality consistency.

In the production of PVC window profiles, it is essential to accurately and precisely weigh and feed PVC, calcite, and additives into the mixers. This system ensures the homogeneity of raw material mixtures, increases production efficiency, and enhances product quality.

Perfect Blends According to Recipes

The facility houses 4 mixers that incorporate PVC, calcite, and 6 different additives from silos, big bags, and bags into production. Each raw material is precisely weighed using its dedicated weighing system. According to the recipe selected via the SCADA system, each raw material is fed into the mixers with the correct formulas. Colorant micro additives are automatically added to the mixers via conveyor with pre-prepared packages, ensuring the production process is managed continuously and efficiently.

The Power of Mixer Blending

VOLDE helps increase the efficiency and product quality of production processes by offering innovative and customizable solutions for PVC window profile manufacturing facilities. Our PVC mixer feeding systems ensure the precision and reliability required in production processes.