Concrete Additive Plant

Concrete Architecture Shaped by Additives

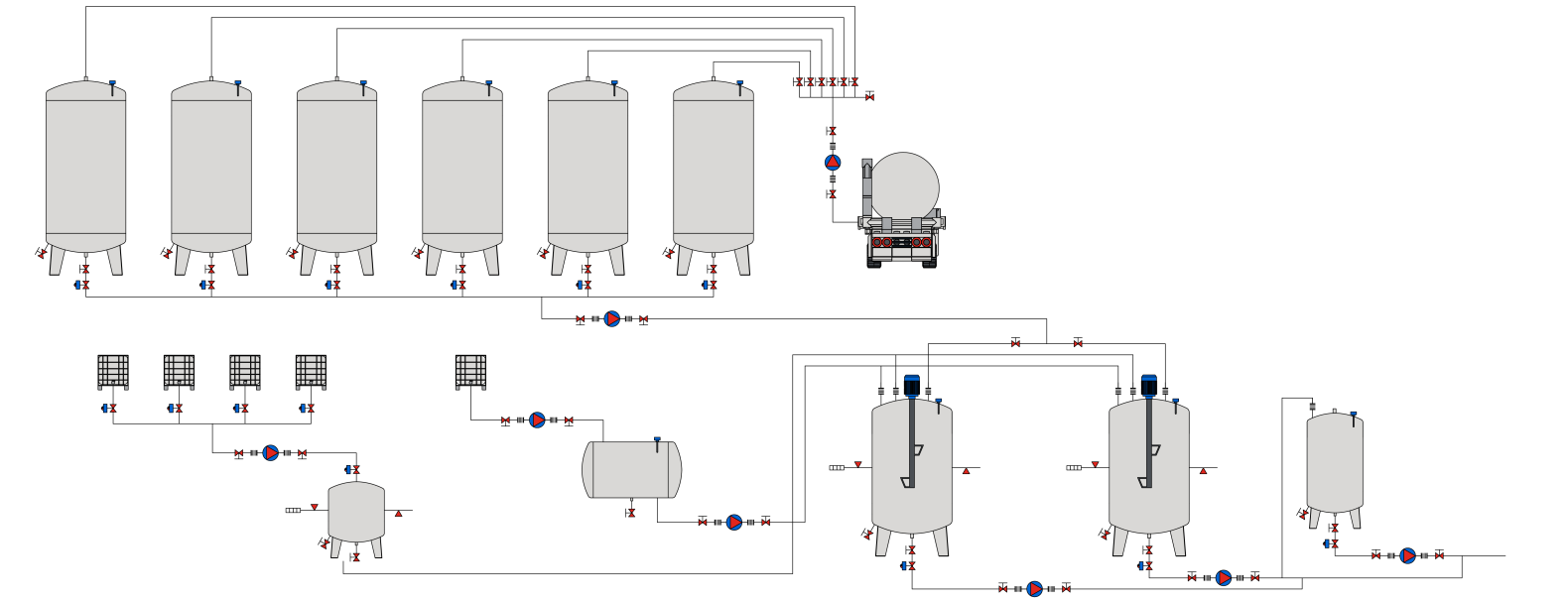

At VOLDE, we aim to enhance the efficiency and product quality of your production process with our liquid concrete additive dosing system developed for concrete additive facilities. This system ensures the accurate and timely mixing of six types of liquid raw materials and four types of additives used in the production of liquid concrete additives, guaranteeing the optimization and quality integrity of concrete production processes.

Effective and accurate dosing and mixing of the liquid and powder additives required for the production of concrete additives composed of six types of liquid raw materials. This system ensures that the homogeneity and quality of concrete additive production are maintained at consistently high standards.

The Rebirth of Concrete

The system consists of six liquid raw material storage tanks and four IBCs for storing additives. These raw materials are automatically fed into one horizontal and one vertical mixing tank according to the recipe entered via the SCADA system. During the mixing process, the necessary powder additives are manually added through the lid on the mixer using bags. The produced liquid concrete is then pumped into tankers with the help of discharge pumps, maximizing precision and efficiency in the production process.

The Liquid Recipe of Concrete

At Volde, we continue to offer innovative and reliable solutions for liquid concrete additive facilities. This system enhances our product quality and the efficiency of our production processes while providing our customers with sustainable and high-quality solutions. With our customized solutions tailored to the needs of your concrete additive facility, you can carry your production into the future.