PVC Mixer Automation

The Power of the Mixer in Cables

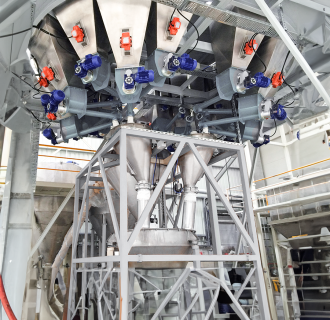

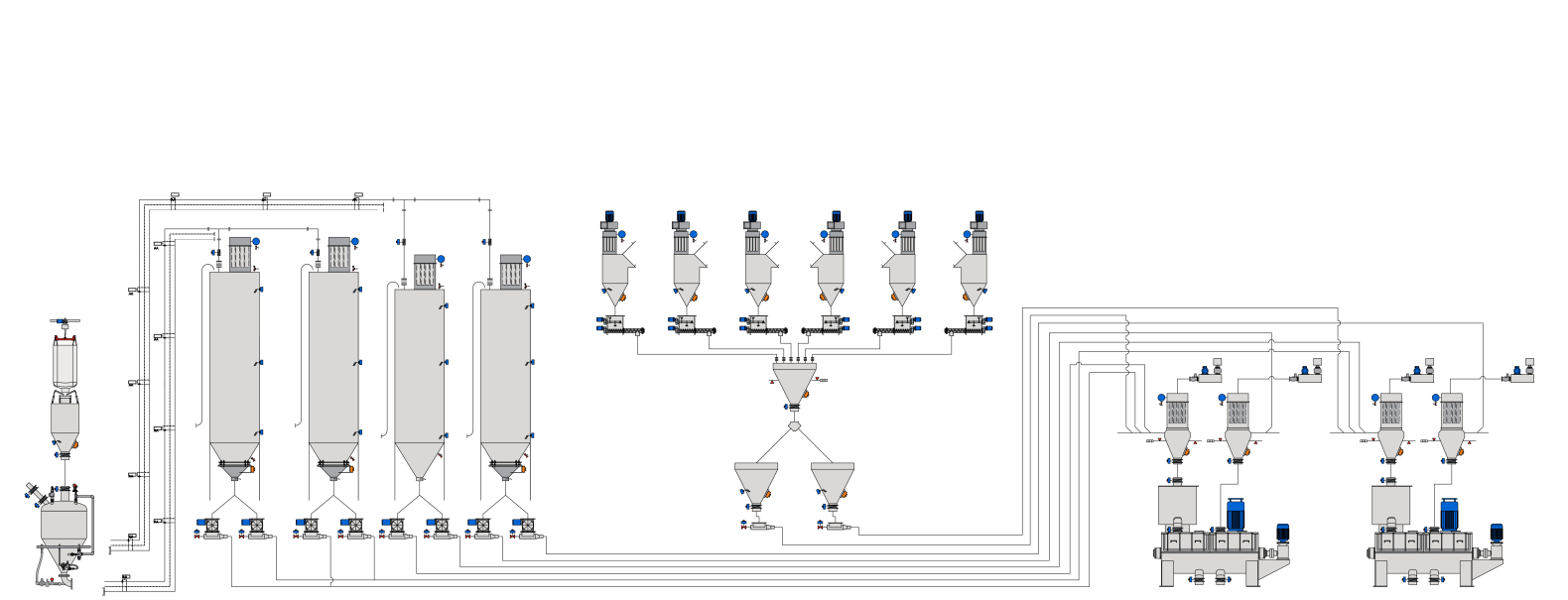

At VOLDE, we aim to enhance the efficiency and product quality of your production process with our PVC mixer automation systems developed for aluminum cable production facilities. These systems ensure the automatic weighing and feeding of powdered raw materials used in the production of cables, sheaths, and fillers into the mixer, thereby guaranteeing the optimization and quality integrity of your production processes.

In aluminum cable production facilities, the PVC Mixer Feeding System ensures the accurate and precise weighing and feeding of PVC, calcite, and other additives used in the production of cables, sheaths, and fillers into the mixers. This system ensures the homogeneity of the raw material mixture, increases production efficiency, and improves product quality.

The Right Mix, Strong Cables

The mixer in the facility ensures the inclusion of PVC, calcite, and three types of additives into production through silos, big bags, and bags. Each raw material is accurately weighed using its specific weighing system. According to the recipe selected via the SCADA system, each raw material is fed into the mixers with the correct formulations, ensuring the production process is managed reliably and efficiently.

Mixer with Precision Blends

At VOLDE, we provide PVC Mixer Automation systems designed specifically for the needs of each customer, ensuring fully automatic control, reliable dosing, and high efficiency in the production process.