Pneumatic Conveying

Dense Phase Conveying

DensPlus

| High capacity and long distance...

DensPlus dense phase pneumatic conveying is the most suitable method for transporting challenging, abrasive, and materials where particle breakage is undesirable. It is also the most preferred system for applications requiring long distances and high conveying capacity.

The system's lower air usage per unit of material allows for transportation at low speeds compared to other conveying methods. This ensures minimal wear on equipment and elbows in the dense phase conveying system that can transport at low speed and low pressure. Thus, it achieves long-lasting operational efficiency with minimal maintenance.

Advantages

|

| Features

|

Dense Phase

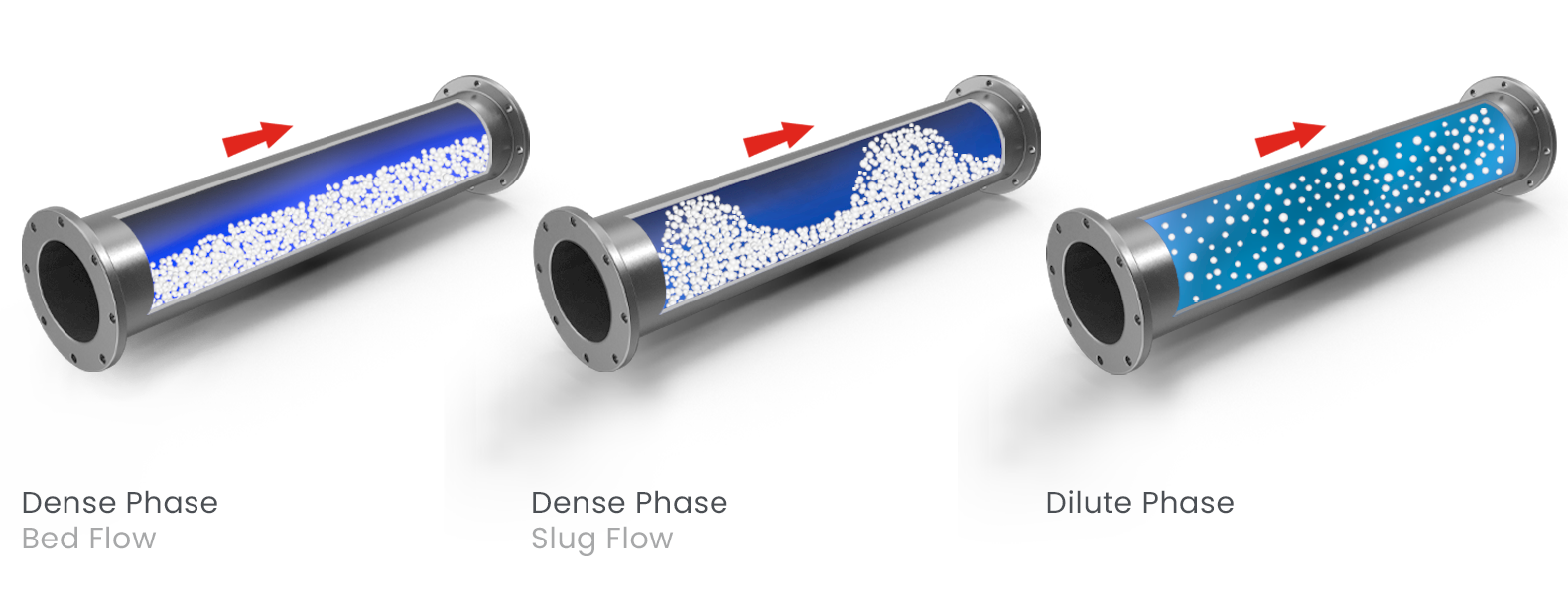

- Dense phase conveying is a pneumatic conveying method that uses lower air velocities (approximately 5 m/s to 10 m/s) compared to dilute phase conveying systems.

- The Material/Air Quantity ratio is higher than other methods.

- Depending on the physical properties, the material moves in blocks (slug flow) along the pipeline.

- While the air pressure requirement in classical dense phase conveying systems is typically 5-6 bar, the DensPlus dense phase conveying system operates with an air pressure between 2-3 bar. Thus, the advantages of low air pressure are evident throughout the entire system.

AirPlus

| Low Pressure, High Benefit...

Unlike conventional systems that operate at high pressure, the DensPlus dense phase conveying system uses the "AirPlus" auxiliary air kit technology for the high-capacity and long-distance transportation of bulk materials in powder and granule form. This technology moves the product consistently by strategically injecting compressed air or nitrogen into various points of the conveying pipeline. As a result, the conveying pressure decreases, allowing the transport of fragile, sensitive, abrasive materials, and mixed formulations without segregation. The AirPlus system not only controls the transport speed but also manages the consumption of compressed air, applying additional transport air to the required points along the pipeline.

- With VOLDE's exclusive AirPlus technology, lower conveying velocities can be achieved, resulting in less impact on the pipeline surfaces. This makes it possible to transport materials without segregation and breakage.

- For the same conveying capacity, the pipe diameter used in the DensPlus dense phase conveying system is smaller than in other methods.

- The distance over which materials can be conveyed with this method is much longer compared to other methods. Projects exceeding 400 meters have been successfully implemented.