Masterbatch Compounding

Mix, Pour, Create

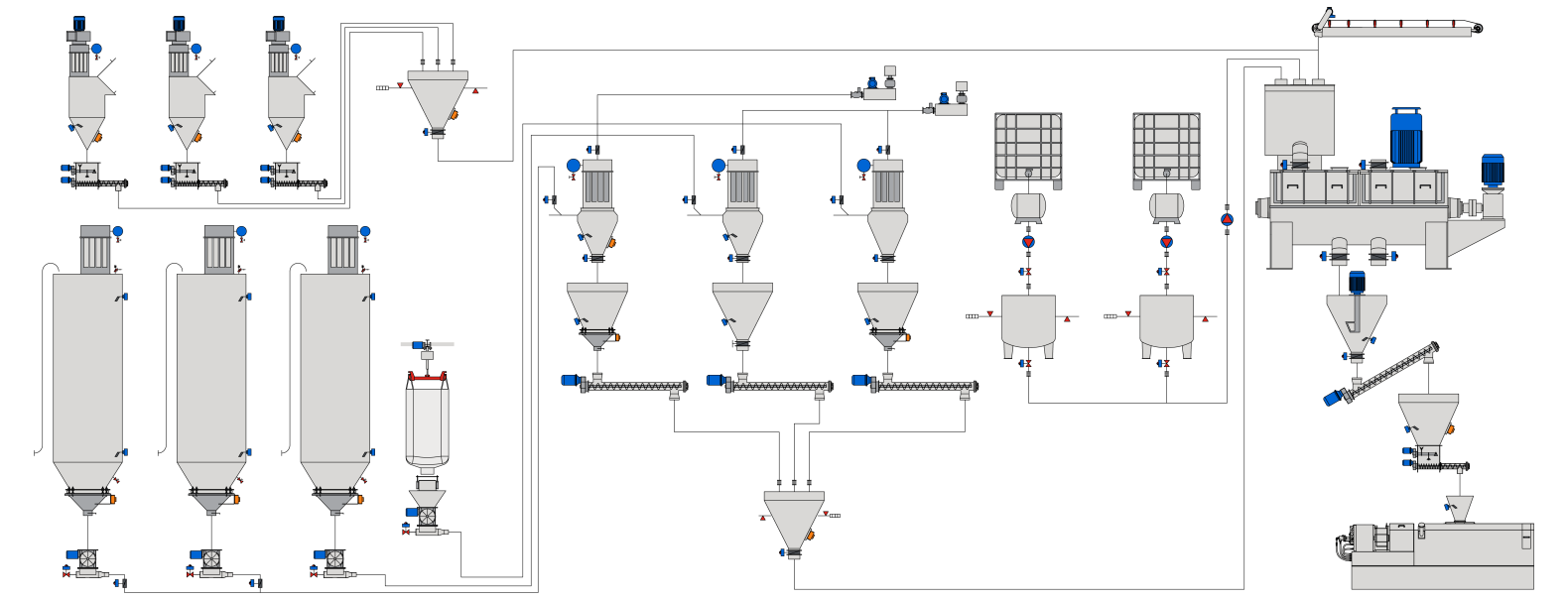

At VOLDE, we maximize efficiency and performance with our Masterbatch production line, developed for the production of high-quality compounds in cable manufacturing facilities. This system ensures the effective and continuous feeding of essential raw materials such as PVC, calcite, stabilizers, and lubricants into the extruder during the cable production process.

The primary goal of the Masterbatch production line is to ensure the extruder is fed with the correct proportions of raw materials continuously and consistently for compound production in cable manufacturing facilities. It allows for the thorough and balanced mixing of raw materials such as PVC, calcite, stabilizers, and lubricants, thereby enhancing product quality and production efficiency.

The Shining Stars of Masterbatch

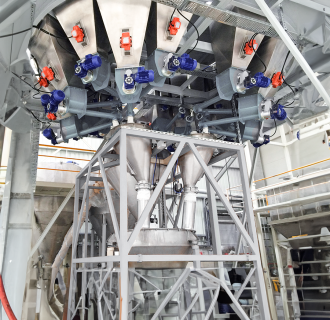

PVC and calcite arriving in big bags, along with stabilizers and lubricants arriving in smaller bags, are transported to the bunkers via the VACUMATE vacuum conveying system. Here, the ready raw materials are discharged based on signals from the gravimetric feeders, ensuring continuous operation of the feeder. The granules produced in the extruder are transported by the VACUMATE vacuum conveying system and filled into big bags using the FULLBAG filling system. This process maximizes the continuity and efficiency of the production process.

The Harmony of Raw Materials

At Volde, we offer customized solutions to meet all your needs when setting up your Masterbatch production lines. The Compound Extruder Feeding System not only enhances dosing precision and conveying efficiency but also maximizes your product quality and production capacity.