Post-Dose Additive Feeding

The Power of High Precision

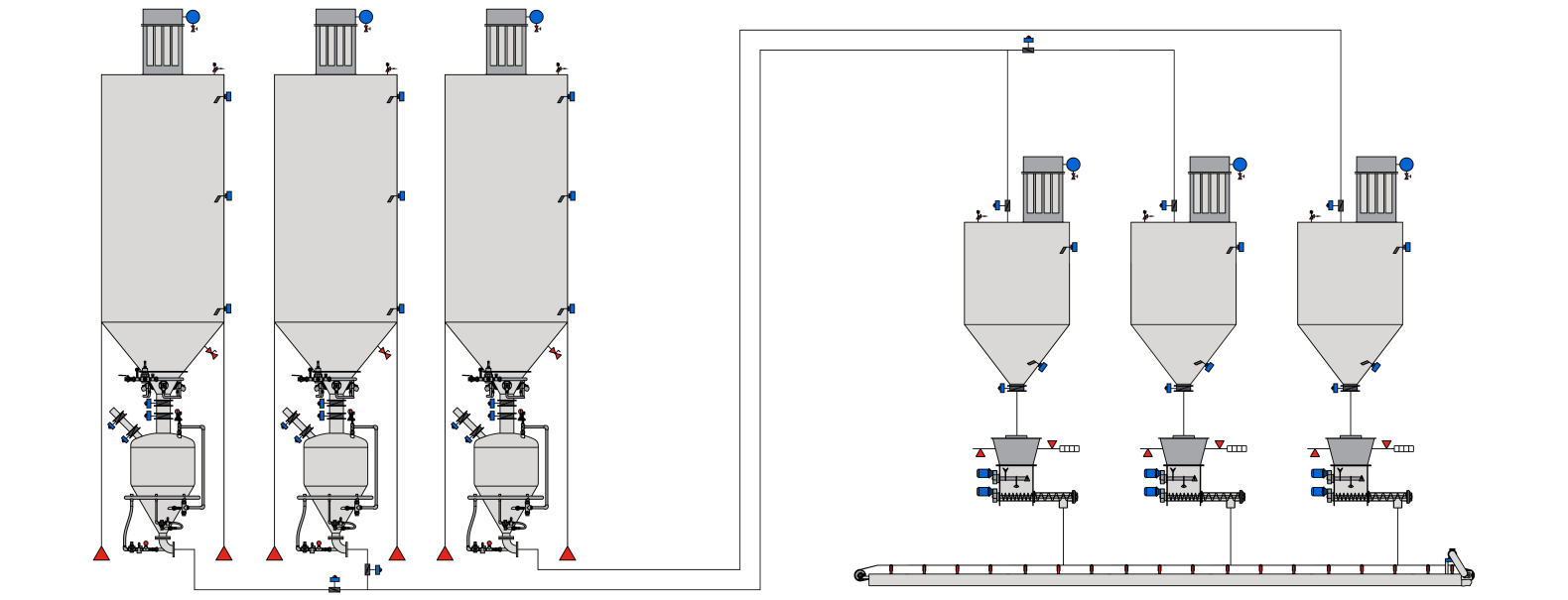

At Volde, we offer a high-precision system specially developed for the gravimetric dosing of post-dose additives used in detergent production. Our gravimetric feeder system for post-dose additives ensures the accurate addition of additives to the production process and achieves a homogeneous mixture. The system is designed to provide a continuous flow in the production process, ensuring a homogeneous mixture with the correct amounts in each batch.

In powder detergent production, the precise dosing of powder additives to achieve a continuous and homogeneous mixture is essential for obtaining high product quality. Our gravimetric feeding system operates with maximum precision in dosing powder additives, aiming to achieve the same homogeneity in every cross-section of the mixture.

Fine Tuning for Tower Powder

Tower powder is conveyed via a collection belt conveyor at a specified kg/h rate. The FEEDGRAM Gravimetric Feeder placed on the conveyor performs continuous and precise dosing based on the real-time capacity entered in the recipe, ensuring percentage feed rate. This guarantees the same homogeneity in every section of the mixture, bringing the product quality in production up to standards.

Integrated Post-Dose Additive Feeding

At VOLDE, we offer integrated post-dose additive feeding facilities tailored to our customers' needs. Our Powder Additives Gravimetric Feeder system not only increases dosing precision but also contributes to continuous flow in production processes and sustainable production practices.